24hr Media Things To Know Before You Get This

24hr Media Things To Know Before You Get This

Blog Article

The 5-Minute Rule for 24hr Media

Table of ContentsThe 7-Second Trick For 24hr MediaWhat Does 24hr Media Mean?The Basic Principles Of 24hr Media The Facts About 24hr Media RevealedThe 10-Second Trick For 24hr Media

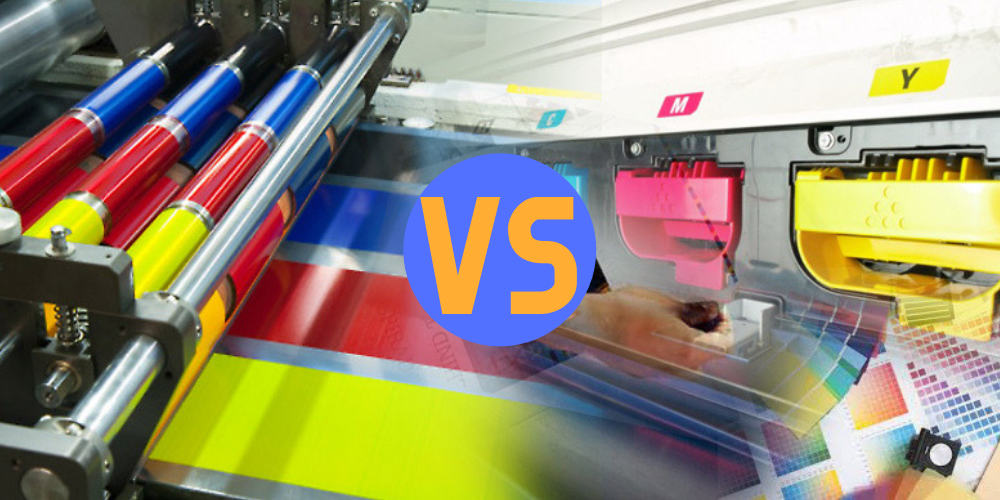

Developments in print innovation are transforming the communications playing field when it concerns quality, affordability and innovative capabilities. Balanced out printing and electronic printing are the significant processes by which print jobs are undertaken both using four-color printing methods. Each alternative has its advantages, supplying different techniques to meet the demands of varied manufacturing projects.

Usually, this has actually been the most regular method for precisely keeping color suits, making it perfect for print runs that just call for static printing such as pre-printed forms, sales brochures, flyers, calling card, and mass postcard mailings. Due to the fixed nature of litho printing, it is not ideal for variable print items that will be sent by mail to specific recipients such as statements, letters, and personalized postcards.

Getting The 24hr Media To Work

The newest improvements in print technology are helping to bring many of countered's advantages into the digital printing world really altering the face of modern printing! There are some essential distinctions between Offset Printing and Digital Printing.

Today's digital print tools is among the most sophisticated on the marketplace. Right here are a few of the greatest advantages of making use of digital printing: dominate the electronic print room, with full-color printing completed in one process and seamlessly published directly from a print documents. Without an extensive set-up procedure, the calibration time of a particular task is shortened, contributing to quicker print time and general shipment.

The inkjet printing process has actually helped to revolutionize the sector along with the high quality and speed of the result. The most up to date inkjet modern technology can publish on typical countered stocks with plain, silk, and shiny surfaces. High-grade digital print paired with software-managed shade administration techniques includes maximum value to publish items and makes production processes much more dependable than offset.

Not known Facts About 24hr Media

(https://www.mixcloud.com/za24media/)

Precise quantities of ink and printer toner are used to avoid waste. Environment-friendly and naturally degradable inks and printer toners are likewise available for even more sustainable printing. Digital print also gets rid of the need to wash plates or coverings with unsafe chemicals at the end of the printing procedure. As the quality of digital print services raises, the benefits end up being progressively obvious and valuable.

Variable data assists organizations reach their exact customers and target market with uniquely-created and personalized web content. As modern technology boosts, the top quality of digital printing has become second-to-none, with greater information, shade match abilities and total precision. Without the demand to clean plates or utilize excess ink, electronic printing is also much less inefficient and usually extra eco-friendly.

("flexo"), entail multiple make-ready actions to move an original picture to a substrate.

Unknown Facts About 24hr Media

Digital informative post printing, with fewer relocating pieces, is more active than balanced out in this regard.

It's a way to blend your product packaging and advertising methods. Reduced set-up time conserves money on the front end. And because these are not huge bulk orders, smaller sized companies can afford to print without having to meet the greater and much more expensive print thresholds of typical printing. Digital printing helps secure your brand name against counterfeiting by incorporating overt and hidden options on your product packaging.

Be certain you work together with a printing and product packaging companion that has the ideal certifications. While eleventh-hour printing and modification are a significant advantage, digital might not constantly be the most effective approach for you. For instance, offset printing has the benefit of cost-effectiveness with huge print runs, especially those with innovative attractive results and specialty finishings.

A Biased View of 24hr Media

The favorable plate, with its smooth surface, attracts oil-based inks and pushes back water. In comparison, the unfavorable plate, with its harsh appearance, takes in water and drives away oil. Rubber rollers are after that used to move the image from the plate to the corrugated surface area.

Corrugated paper can in some cases show to be a challenging surface to print on, yet Litho prints to a different surface and is after that laminated to it, making it easy to print high-grade pictures. It can be exceptionally consistent, even for long terms. In fact, the extra you publish, the cheaper the expenses come to be for Litho.

What Litho does not give you is specifically what Digital does, personalization. Costly set up Longer turn-around No Variable Data Printing Smaller shade range, shades can be less bright Digital printing is the process of printing electronic photos directly onto the corrugated substratum using a single-pass, direct-to-corrugate strategy.

Report this page